Custom Mold Components Lifter

Brand Name:Hamsan Tooling

Mold Base:N/A

Mold Material:P20

Tolerance:+/-0.01mm

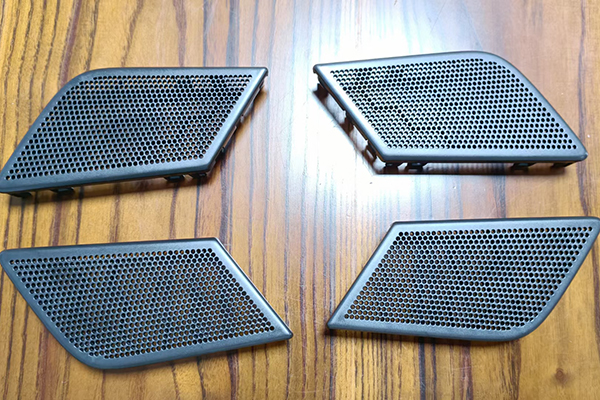

Shaping Mode:Plastic Injection Mold

Design Software:AutoCAD;NX;ProE

Packaging Details:Wooden case

Delivery Time:14 days manufacturing lead time

Products Details

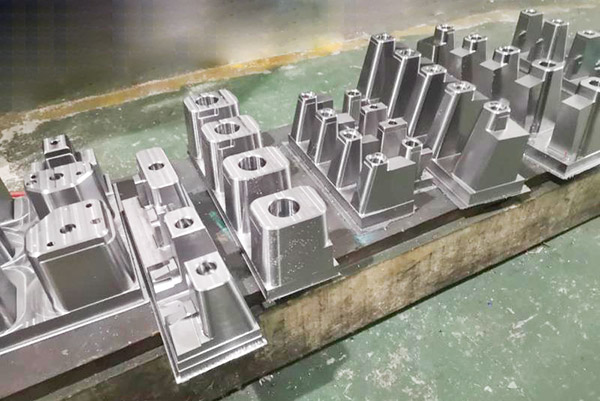

Hamsan Tooling has been manufacturing mold components and accessories since 2004. HST Mold prides itself on its in-house design and fabrication. We employ highly skilled professional operators to operate our drill presses, CNC machines, EDM machines, proprietary mirror EDM machines and die polishers.

Why Choose Us:

1. Hamsan was founded in 2004, Cover an area of 5000 sqms Plant; Provide OEM/ODM Service

2. Certified by ISO90001, SGS,CE,UL etc

3. Over 15 years experience in Mold Making & Plastic Injection Parts Mass Production

4. Integrating R&D, QC System & Marketing Sales.

5. One-stop Service of Custom mold design from Initial drawing design, Material selection assistance, Mold structure/Mold flow analysis, Trial & mass production to Final mold assembly & shipment.

Specififaction:

Project Management:

Product DFM ⇒ Mold Design ⇒ Material Preparation ⇒ CNC Machining ⇒ EDM Machining ⇒ Grinding and Drilling Machining ⇒Wire Cutting ⇒ Polishing ⇒ Mold Fitting⇒ Mold Trail ⇒ Sample Inspection ⇒ Sample Approved ⇒ Mass Production ⇒ Mold(Product) Packing ⇒ Mold Delivery ⇒ After Sale Service

Look forward to hearing your inquiry.

Tag: Gold Plating Mold Lifter OEM, EDM Chrome Plating Mold Lifter, Custom Mold Components Lifter in-molding

Why Choose Us:

1. Hamsan was founded in 2004, Cover an area of 5000 sqms Plant; Provide OEM/ODM Service

2. Certified by ISO90001, SGS,CE,UL etc

3. Over 15 years experience in Mold Making & Plastic Injection Parts Mass Production

4. Integrating R&D, QC System & Marketing Sales.

5. One-stop Service of Custom mold design from Initial drawing design, Material selection assistance, Mold structure/Mold flow analysis, Trial & mass production to Final mold assembly & shipment.

Specififaction:

Project Management:

Product DFM ⇒ Mold Design ⇒ Material Preparation ⇒ CNC Machining ⇒ EDM Machining ⇒ Grinding and Drilling Machining ⇒Wire Cutting ⇒ Polishing ⇒ Mold Fitting⇒ Mold Trail ⇒ Sample Inspection ⇒ Sample Approved ⇒ Mass Production ⇒ Mold(Product) Packing ⇒ Mold Delivery ⇒ After Sale Service

Look forward to hearing your inquiry.

Tag: Gold Plating Mold Lifter OEM, EDM Chrome Plating Mold Lifter, Custom Mold Components Lifter in-molding